Digital Load Cell Converter (DCell)

View more videos on

Our

YouTube Channel !

- Strain gauge to RS485 or CAN digital load cell converter

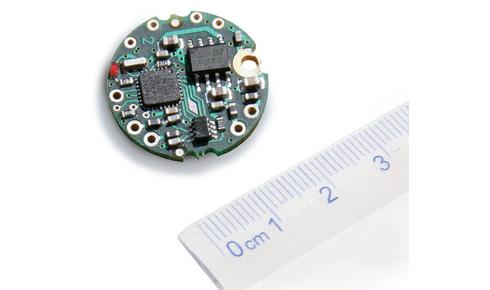

- Low profile, small 20 mm diameter for mounting inside sensor

- Auto calibration or direct entry of mV/V with linearisation

- Ultra high performance, resolution of 1 part in 200,000 (18bit)

- Error reporting including strain gauge fault conditions

- Programmable dynamic filter

- A miniature digital temperature sensor module for wiring to DCell/DSC temperature sensor pcb board is also available (shown on thumbnail image on left)

- Option of an in-line enclosure (shown on thumbnail image on left)

- FREE ! - Software enabling 24 DCell or DSCs to be viewed and logged simultaneously - see more here

Very high performance embedded digital load cell converter or strain gauge digitizer module signal converter supplied in a miniature format designed specifically to be incorporated directly into strain gauge sensors such as load cells, pressure transducers and torque sensors. The DCell offers high speed and high precision digitizing capabilities, along with linearization and temperature compensation.

The DCell has conversion of standard strain gauge load cells to digital load cells.

This high performance digital load cell converter embeds directly into load cells, pressure transducers and/or torque sensors

The DCell output formats options include the RS485, ASCII, Modbus, MantraCAN (J1939). All are 4 wire bus and power formats offering connection of up to 32 sensors on just 4 wires.

DCell Additional features are:-

Remote shunt calibration

Temperature compensation

Peak and trough recording

Long cable lengths up to 1000m

Try our ready to go Evaluation Kit which includes one free DCell or DSC card.

First select the DCell you require and ask for the appropriate Evaluation Kit as an accessory item. See our Videos above for 'Getting Started with the Evaluation Kit' video.

For packaged options for mounting external to the sensor,- see models DSC Strain Gauge or Load Cell Digitiser Module, DSJ1 Strain Gauge or Load Cell Digitiser Module (1 Channel) and DSJ4 Strain Gauge or Load Cell Digitiser Module (4 Channel).

DCell |

|||||

|---|---|---|---|---|---|

| Description | Min | Typical | Max | Units | |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc | |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** | |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** | |

| Bridge Sensitivity | -3 | +3 | mV/V | ||

| Offset Temperature Stability | 1 | 4 | ppm/ºC | ||

| Gain Temperature Stability | 3 | 5 | ppm/ºC | ||

| Offset Stability with Time | 0.002 | 0.008 | %FR | ||

| Gain Stability with Time | 30 | ppm of FR/1st Year | |||

| Non Linearity | 0.0005 | 0.0025 | %FR | ||

| Internal Resolution | 16 Million | Counts/Divisions | |||

| Resolution @ 1Hz (Noise Stable) * | 200,000 | Counts/Divisions | |||

| Resolution @ 10Hz (Noise Stable) * | 120,000 | Counts/Divisions | |||

| Resolution @ 100Hz (Noise Stable) * | 50,000 | Counts/Divisions | |||

| Resolution @ 500Hz (Noise Stable) * | 18,000 | Counts/Divisions | |||

| Optional Temperature Measurement Resolution | 0.1 | ºC | |||

| Optional Temperature Measurement Accuracy | 1 | ºC | |||

| Notes: From original offset at any time. *Stability over 100 second period. **Subject to supply voltage. See Electrical Specification | |||||

| Electrical | |||||

| Power Supply Voltage | 5.4 | 12 | 18 | V dc | |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | |||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | ||

| Power @ 10V Supply (350R Bridge) | 350 | mW | |||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms | |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms | |

| Excitation System | 4 wire | ||||

| Environmental | |||||

| Operating Temperature Range | -40 | 85 | °C | ||

| Operating Temperature Range for OIML 6000d | -10 | 55 | °C | ||

| Storage Temperature | -40 | 85 | °C | ||

| Humidity | 0 | 95 | %RH on Condensing | ||

| Communications | |||||

| RS485 Data Rate | 2,400 | 230k | Baud | ||

| CAN Bit Rate | 20k | 1M | Bits/Sec | ||

| Note: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec | |||||

| Protocols | |||||

| Available Now: ASCII, MANTRABUS II, Modbus RTU (via RS485) and MantraCAN - Contact Mantracourt for details. Please Note: MantraCAN products will only work with Mantracourt software up to and including Windows Vista. |

|||||

DLCS Industrial Stability |

|||||

| Description | Min | Typical | Max | Units | |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc | |

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms** | |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms** | |

| Bridge Sensitivity | -3 | +3 | mV/V | ||

| Offset Temperature Stability | 5 | 10 | ppm/C | ||

| Gain Temperature Stability | 30 | 50 | ppm/C | ||

| Offset Stability with Time | 0.0035 | 0.016 | %FR | ||

| Gain Stability with Time | 300 | ppm of FR /1st Year | |||

| Non Linearity | 0.0005 | 0.0025 | % FR | ||

| Internal Resolution | 16 Million | Counts/Divisions | |||

| Resolution @ 1Hz (Noise Stable) * | 66,000 | Counts/Divisions | |||

| Resolution @ 10Hz (Noise Stable) * | 40,000 | Counts/Divisions | |||

| Resolution @ 100Hz (Noise Stable) * | 10,000 | Counts/Divisions | |||

| Resolution @ 500Hz (Noise Stable) * | 5,000 | Counts/Divisions | |||

| Optional Temperature Measurement Resolution | 0.1 | ºC | |||

| Optional Temperature Measurement Accuracy | 1 | ºC | |||

| Notes: From original offset at any time. *Stability over 100 second period. ** Subject to supply voltage. See Electrical Specification | |||||

| Electrical | |||||

| Power Supply Voltage | 5.6 | 12 | 18 | V dc | |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | |||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | ||

| Power @ 10V Supply (350R Bridge) | 350 | mW | |||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms | |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms | |

| Excitation System | 4 wire | ||||

| Environmental | |||||

| Operating temperature range | -40 | 85 | °C | ||

| Storage temperature | -40 | 85 | °C | ||

| Humidity | 0 | 95 | %RH Non Condensing | ||

| Communication | |||||

| RS485 Data Rate | 2,400 | 230k | Baud | ||

| CAN Bit Rate | 10k | 1M | Bits/Sec | ||

| Note: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec | |||||

| Protocols | |||||

| Available Now: ASCII, MANTRABUS II, Modbus RTU (via RS485) and MantraCAN - Contact Mantracourt for details. Please Note: MantraCAN products will only work with Mantracourt software up to and including Windows Vista. |

|||||

| Support Modules | |||||

| Instrument Explorer Software free PC software, RS232 - RS485 Convertor, DCell Evaluation Kits | |||||

| Environmental | |||||

| CE Environmental Approvals | European EMC Directive 2014/30/EC, Low Voltage Directive 2014/35/EC | ||||

Documents

- DSC/DLC User Manual : Updated DSC & DCell Manual incorporating: RS-232/RS-485, CANOpen and MantraCAN versions of the DCELL(DLC) and DSC product

- DCell Product Sheet

- Evaluation Kit For DCell & DSC Overview : All you need to evaluate the DCell & DSC at your PC!

Software

- Instrument Explorer : This software allows the user to quickly set up and start to use the digitisers and indicators that Mantracourt offers. Capabilities include event monitoring and data logging, as well as calibration and configuration.

- DSC 24 Channel Logging : Version 1.3.2 View and log data from up to 24 DSC, DLC or DSCUSB modules.

- DSC / DLC Toolkit : Version 1.0.8 2023 This toolkit allows configuration, calibration, logging and parameter management of the DSC, DLC and DS485DIS modules.

Product order options

Please read the following before selecting the options for this product:

The Embedded Digital Load Cell Converter or Strain Gauge Digitizer Module, the DCell is available in two main versions, differing only in performance and cost. These versions are the industrial stability (suitable for most industrial measurements) and the high stability (for very high precision measurements). Either type is available with various communications options, selectable from the list below.

For feasibility tests or evaluation, try our DCell Evaluation Kit which includes one free DCell from the list below. See EVALKITS.

| High Stability | Code |

|---|---|

| In Cell ASCII Protocol | DLCHASC |

| In Cell MANTRABUS Protocol | DLCHMAN |

| In Cell MODBUS Protocol | DLCHMOD |

| In Cell MantraCAN Protocol | DLCHMCAN |

| Incell CANopen Protocol | DLCHCOP |

| Industrial Stability | Code |

| In Cell ASCII Protocol | DLCSASC |

| In Cell MANTRABUS Protocol | DLCSMAN |

| In Cell MODBUS Protocol | DLCSMOD |

| In Cell MantraCAN Protocol | DLCSMCAN |

| Incell CANOpen Protocol | DLCSCOP |

| Options | Code |

| In-Line Housing for Load Cell Amplifiers & Digital Converters (*Ex Works) | ILE |

| Display | Code |

| Display Module with RS485 Input | DS485DIS |

| Accessories | Code |

| Evaluation Kit for CAN (*Ex Works) | EVAL-KIT-CAN |

| Evaluation Kit for RS485 (*Ex Works) | EVAL KIT 485 |

| Digital temperature sensor module for wiring to DCell/DSC | DTEMP |

These are the following industries and applications in which this product has been used:

- Civil Engineering - Opera House Relocation

- Agriculture - Weighing System for Mango Farm

- Marine - Mast Force Monitoring in Racing Yachts

- Marine - Prop Supports in Dry Dock

- Industrial Processing - Consistency in Repeatable Weld Joints

- Test & Measurement - Tension Sensors For The British Antarctic Survey

- Live Performance - Monitoring Peak Loads of Advertising Banners

- Torque Measurement - Steering Torque Sensors for Assessment Situations

Mount Board for a Single Digital Load Cell Converter

Mount Board for 4 x Digital Load Cell Converters

In-Line Housing for Load Cell Amplifiers and Digital Converters

- Q: You offer two versions – industrial stability and high stability - of the DSC and DCell, what is the difference?

A: The Industrial Version offers 25ppm basic accuracy (equates to 16 bit resolution). The High Stability version offers 5ppm basic accuracy (equates to 18 bit resolution) with comparable stability which far exceeds standard instrument performance.

- Q: Are the DSC devices low-power?

A: Yes, low-voltage DC supply (5.6V min), typically 40mA for RS485 &.52mA for RS232 (including 350R strain gauge).

- Q: Is there adjustable sensitivity?

A: Yes, the DSC devices can be configured for standard 2.5mV/V full-scale strain gauges as supplied. A single additional resistor configures the input between 0.5 and 100 mV/V full-scale.

- Q: Do you offer linearity compensation?

A: Yes, advanced 7-point linearity compensation.

- Q: Are there self-diagnostics?

A: Yes, the DSC devices offer continuous monitoring for faults such as strain overload, over/under-temperature, broken sensors or unexpected power failure. All fault warnings are retained on power-fail.

.jpg&w=120&hash=b3cbc6164e535bfea8c82473205d4123)

.jpg&w=120&hash=661e14e204b70b79eebd5dc61fbff3f3)

.png&h=40&f=png&far=1&bg=FFFFFF&hash=d1c7fb09682d201239c9925607fc3432)