Digital Load Cell Converter CardDSC

SKU: DSC

Description

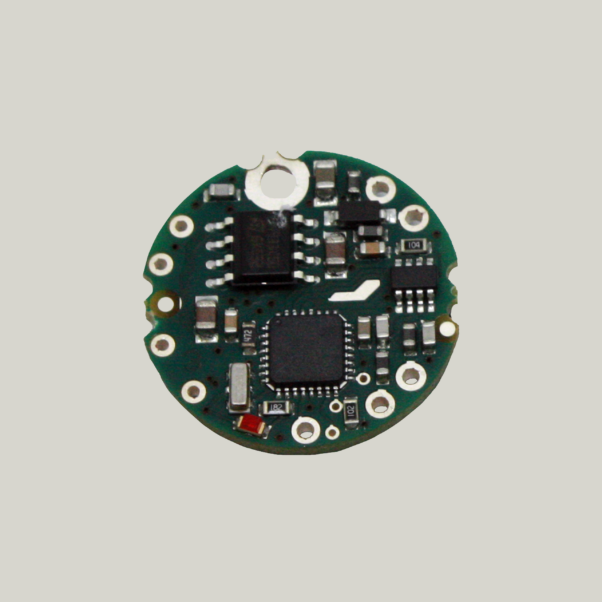

The DSC is a high-performance digital load cell converter module designed for use with strain gauge sensors, including load cells, pressure transducers, and torque sensors. It provides fast, accurate signal conversion with linearisation and temperature compensation, enabling precise measurement in demanding applications.

Available output formats include RS232, RS485, CAN, ASCII, Modbus, and MantraCAN (J1939), offering flexible integration with PLCs, control systems, and monitoring platforms.

For OEM use, the same electronics are available in a compact format (see DCell), ideal for internal mounting within the sensor.

The DSC is also offered in a range of housed configurations:

-

As an IP65-rated module for standalone installation

-

Within a single-channel DSJ1 display and junction box

-

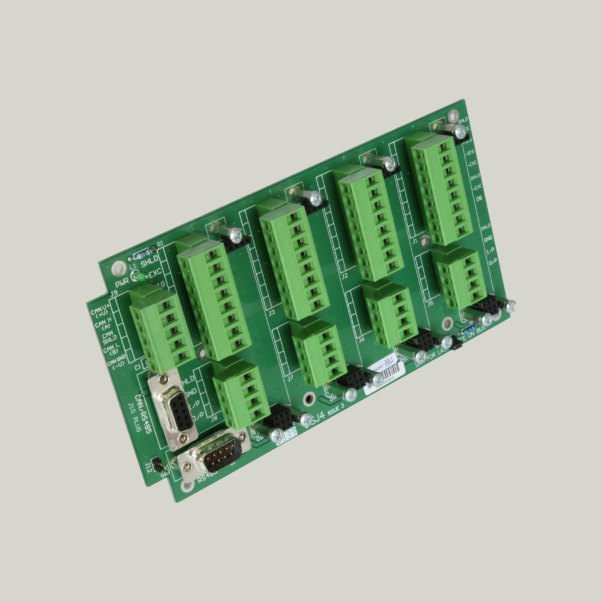

Within a four-channel DSJ4 system for multi-sensor installations

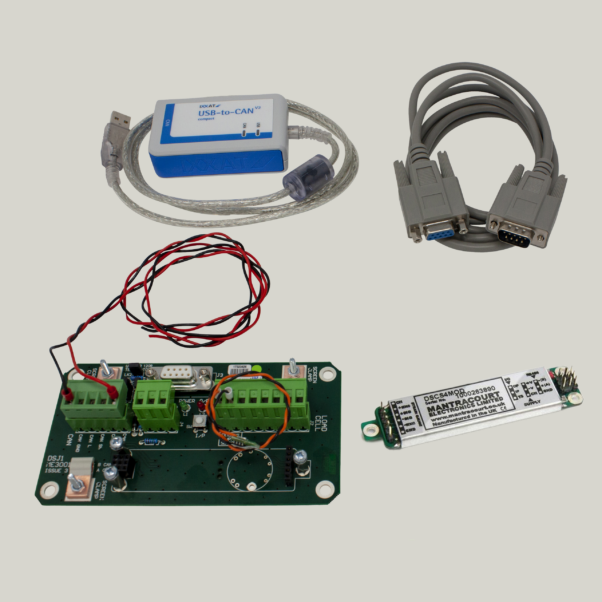

An Evaluation Kit is available, which includes one free DSC or DCell module. Please specify your preferred module when ordering. The free toolkit software enables setup, logging, and live viewing of up to 24 DSC or DCell units simultaneously.

Product Features & Benefits

-

Converts strain gauge inputs to digital output via RS232, RS485, or CAN (ASCII, Modbus, MantraCAN/J1939 protocols supported)

-

OEM miniature PCB format for easy integration into custom sensor systems

-

Ultra-high performance with up to 18-bit resolution (1 part in 200,000)

-

High-speed data output with update rates up to 500 readings per second

-

Auto calibration or direct entry of mV/V values with user-defined linearisation

-

Programmable dynamic filtering to optimise response and stability

-

Built-in temperature compensation for reliable operation in varying environments

-

Peak and trough (valley) recording for monitoring dynamic loads

-

Error reporting includes strain gauge fault detection and overload conditions

-

Remote shunt calibration via software command or digital input

-

Free toolkit software enables up to 24 DSC or DCell modules to be viewed and logged simultaneously

-

Optional temperature sensor board for inline thermal measurement

-

Available in board-only format or housed in IP65 enclosures

-

Compatible with DSJ1 (1-channel) and DSJ4 (4-channel) junction box displays

-

Try the ready-to-go Evaluation Kit with free DSC or DCell card — ideal for setup and testing

Specifications

High Stability |

||||

|---|---|---|---|---|

| Description | Min | Typical | Max | Units |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** |

| Bridge Sensitivity | -3 | +3 | mV/V | |

| Offset Temperature Stability | 1 | 4 | ppm/ºC | |

| Gain Temperature Stability | 3 | 5 | ppm/ºC | |

| Offset Stability with Time | 0.002 | 0.008 | %FR | |

| Gain Stability with Time | 30 | ppm of FR/1st Year | ||

| Non Linearity | 0.0005 | 0.0025 | %FR | |

| Internal Resolution | 16 Million | Counts/Divisions | ||

| Resolution @ 1Hz (Noise Stable) * | 200,000 | Counts/Divisions | ||

| Resolution @ 10Hz (Noise Stable) * | 120,000 | Counts/Divisions | ||

| Resolution @ 100Hz (Noise Stable) * | 50,000 | Counts/Divisions | ||

| Resolution @ 500Hz (Noise Stable) * | 18,000 | Counts/Divisions | ||

| Optional Temperature Measurement Resolution | 0.1 | ºC | ||

| Optional Temperature Measurement Accuracy | 1 | ºC |

Notes: From original offset at any time. *Stability over 100 second period. **Subject to supply voltage. See Electrical Specification

| Electrical | Min | Typical | Max | Units |

|---|---|---|---|---|

| Power Supply Voltage | 5.6 | 12 | 18 | V dc |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | ||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | |

| Power @ 10V Supply (350R Bridge) | 350 | mW | ||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms |

| Excitation System | 4 Wire |

| Environmental | Min | Typical | Max | Units |

|---|---|---|---|---|

| Operating Temperature Range | -40 | 85 | °C | |

| Operating Temperature Range for OIML 6000d | -10 | 55 | °C | |

| Storage Temperature | -40 | 85 | °C | |

| Humidity | 0 | 95 | %RH on Condensing |

| Communications | Min | Typical | Max | Units |

|---|---|---|---|---|

| RS485 Data Rate | 2,400 | 230k | Baud | |

| CAN Bit Rate | 20k | 1M | Bits/Sec |

Note: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec

Industrial Stability |

||||

|---|---|---|---|---|

| Description | Min | Typical | Max | Units |

| Bridge Excitation | 4.5 | 5 | 5.25 | dc |

| Sensor Impedance up to 18V Supply | 320 | 350 | 5,000 | ohms** |

| Sensor Impedance up to 12V Supply | 120 | 350 | 5,000 | ohms** |

| Bridge Sensitivity | -3 | +3 | mV/V | |

| Offset Temperature Stability | 5 | 10 | ppm/ºC | |

| Gain Temperature Stability | 30 | 50 | ppm/ºC | |

| Offset Stability with Time | 0.0035 | 0.016 | %FR | |

| Gain Stability with Time | 300 | ppm of FR/1st Year | ||

| Non Linearity | 0.0005 | 0.0025 | %FR | |

| Internal Resolution | 16 Million | Counts/Divisions | ||

| Resolution @ 1Hz (Noise Stable) * | 66,000 | Counts/Divisions | ||

| Resolution @ 10Hz (Noise Stable) * | 40,000 | Counts/Divisions | ||

| Resolution @ 100Hz (Noise Stable) * | 10,000 | Counts/Divisions | ||

| Resolution @ 500Hz (Noise Stable) * | 5,000 | Counts/Divisions | ||

| Optional Temperature Measurement Resolution | 0.1 | ºC | ||

| Optional Temperature Measurement Accuracy | 1 | ºC |

| Electrical | Min | Typical | Max | Units |

|---|---|---|---|---|

| Power Supply Voltage | 5.6 | 12 | 18 | V dc |

| Power Supply Noise/Ripple | 100 | mV ac pk-pk | ||

| Power Supply Current (350R Bridge) | 45 | 60 | mA | |

| Power @ 10V Supply (350R Bridge) | 350 | mW | ||

| Sensor Impedance up to 18v Supply | 320 | 350 | 5,000 | ohms |

| Sensor Impedance up to 12v Supply | 120 | 350 | 5,000 | ohms |

| Excitation System | 4 Wire |

| Environmental | Min | Typical | Max | Units |

|---|---|---|---|---|

| Operating Temperature Range | -40 | 85 | °C | |

| Storage Temperature | -40 | 85 | °C | |

| Humidity | 0 | 95 | %RH on Condensing |

| Communications | Min | Typical | Max | Units |

|---|---|---|---|---|

| RS485 Data Rate | 2,400 | 230k | Baud | |

| CAN Bit Rate | 10k | 1M | Bits/Sec |

Note: Update speeds are selectable to 1, 2, 5, 10, 20, 50, 60, 100, 200, 300, 500 Samples/Sec

Dimensions

87.4mm x 20 mm x 8.5mm

Downloads

FAQ

| Q | You offer two versions – industrial stability and high stability – of the DSC and DCell, what is the difference? |

| A | The Industrial Version offers 25ppm basic accuracy (equates to 16 bit resolution). The High Stability version offers 5ppm basic accuracy (equates to 18 bit resolution) with comparable stability which far exceeds standard instrument performance. |

| Q | Are the DSC devices low-power? |

| A | Yes, low-voltage DC supply (5.6V min), typically 40mA for RS485 &.52mA for RS232 (including 350R strain gauge). |

| Q | How about multiple output options? |

| A | We offer a choice of two communications standards: RS232 (DSC only) or RS485, with a choice of three different protocols: ASCII, MODBUS or MANTRABUS, for ease of integration. All variants provide identical features and performance. |

| Q | Is there adjustable sensitivity? |

| A | Yes, the DSC devices can be configured for standard 2.5mV/V full-scale strain gauges as supplied. A single additional resistor configures the input between 0.5 and 100 mV/V full-scale. |

| Q | Do you offer linearity compensation? |

| A | Yes, advanced 7-point linearity compensation. |

| Q | Is there options for serial output and how many devices can be used on a bus? |

| A | Yes the DSC products offer lower-cost cabling, improved noise immunity, and longer cable runs with no accuracy penalty. Device addressing allows up to 253 devices on a single bus, drastically reducing cabling cost and complexity. Two-way communications allow in-situ re-calibration, multiple outputs and diagnostics. No separate measuring instruments needed. |

| Q | How do you calibrate the DSC? |

| A | We offer digital calibration which is completely drift-free, adjustable in-system and/or in-situ via standard communications link. Two independent calibration stages for load cell-and-system-specific adjustments. Programmable compensation for non-linearity and temperature corrections. Calibration data is also transferable between devices for in-service replacement |

| Q | Are there self-diagnostics? |

| A | Yes, the DSC devices offer continuous monitoring for faults such as strain overload, over/under-temperature, broken sensors or unexpected power failure. All fault warnings are retained on power-fail. |

| Q | What is the mean time between failure (MTBF) rate of the DCell and DSC? |

| A | 230,000 working hours. Download MTBF calculated hours here. |

Need Assistance?

Get in touch and we’ll help you

to identify the right solution.